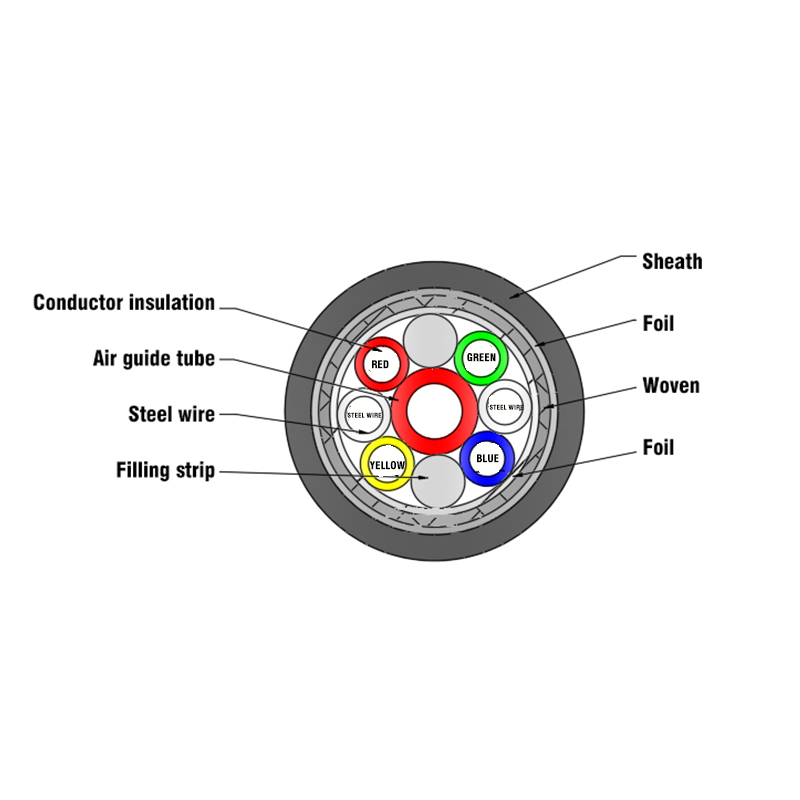

Silicone rubber cables are widely used in industrial equipment, robots, mobile devices, and other applications where frequent bending is required due to their excellent flexibility and temperature resistance.

- +86-17751331676

- 18690048081@163.com

- Liulin Town Industrial Park, Fengxiang District, Baoji City, Shaanxi Province